A-Type vs H-Type Battery Cage: What’s the Difference (and Which One Fits Your Poultry Farm)?

Choosing the wrong battery cage layout can lock your poultry farm into high labor, poor ai…

Choosing the wrong battery cage layout can lock your poultry farm into high labor, poor airflow, or hard upgrades. Agitate: That mistake shows up fast—uneven egg production, higher stress in the chicken flock, and messy manure handling. Solution: In this guide, I’ll compare a-type and h-type systems in plain terms so you can pick the right cage system quickly and confidently.

The main difference between an A-type battery cage and an H-type battery cage is structure and automation capacity. A-type cages form an “A” frame and are usually simpler and lower cost, making them common for smaller or budget-focused farms. H type systems use stacked, vertical rows with stronger frames, better space utilization, and easier integration of automated feeding, egg collection, and manure removal, which fits larger, modern layer battery cage system projects.

نظام أقفاص تربية الدجاج الأوتوماتيكي من النوع H

What is a battery cage system in modern poultry production?

A-type and H-type: what they look like and how the cage type changes operations

Which cage system gives better space utilization?

Automation readiness: feeding, watering, egg collection, manure removal

Ventilation and climate control: which supports stable flock performance?

Labor, reduce labor, and labor costs: what changes in daily work?

Bird welfare and management: what you can do inside each chicken house

Durability, galvanize, wire mesh, and service life

Cost & ROI: how to compare CapEx and productivity

How to decide fast: a step-by-step selection checklist + FAQs

A battery cage setup is a structured cage system used for layer chicken production. Each hen lives in a defined cage space, with feeding and drinking lines placed in front, and a slope that allows eggs to roll onto an egg collection path. In many projects, this becomes a complete layer cage system with house design, ventilation, lighting, water, feed, and manure management working together.

From an engineering supplier point of view, we treat a battery cage system like a “factory line” for eggs. The chicken does one job—lay eggs—while the poultry cage setup keeps feed, water, air, and hygiene consistent. That consistency is what protects egg production efficiency and makes your farm easier to scale.

A-type cages are built like an “A” frame—two slanted sides meeting at the top. This design often uses fewer materials and can be easier to install in simpler houses. Many farms call it type layer cages or a-type layer cages. It’s a classic solution, especially where budget and quick installation matter.

H type designs (often called h-type cages or h type layer battery cage) stack cages in vertical lines, supported by stronger “H” frames. This structure is more rigid, especially in multi-tier setups. When a farm wants modern, high-throughput performance, h-type battery cages usually become the default because they handle upgrades better—especially automation, long houses, and higher bird counts.

Here’s the practical point: the cage type changes your daily flow. It affects how air moves in the chicken house, how manure removal is handled, and how smoothly eggs travel to collection and packing.

If you’re tight on land area, space utilization becomes the make-or-break factor. In many cases, H type systems win on vertical stacking because they can run more tiers in a stable frame. That means more birds per building footprint—helpful for large-scale farms or investors aiming for high output per house.

A-type cages can still deliver good density, but the A-frame geometry can limit how high you stack compared with an H-frame layout. So for a poultry farm with limited building width or where you must maximize birds per house length, H type often gives you more flexibility.

Simple rule of thumb:

If your project goal is “maximize birds per house,” H type is often easier to scale.

If your goal is “start quickly with controlled investment,” A-type cages can be a practical first step.

In a modern system, automation is not a luxury—it’s what protects your margin when wages rise and skilled labor is hard to find. The key automation modules include:

Egg collection (belt or rod systems)

Automatic feeding (hopper + auger/chain feed lines)

Nipple drinking lines

Manure removal (belt at the bottom, scraping, or drying options)

H type is usually more “automation-friendly” because the frame supports straight-line belt routes and consistent alignment across tiers. In many designs, the belt at the bottom of each tier makes manure removal predictable and reduces ammonia buildup. That helps control manure moisture and improves house hygiene.

A-type cages can also integrate automated systems, but it may require more careful design to route belts and keep access safe. In some older-style houses, manual or semi-automatic routines are still used. That’s not “wrong”—it just means your automation upgrade path may be narrower.

قفص بطارية أوتوماتيكي من النوع H

Ventilation is one of the most underrated parts of a battery cage system decision. Even the best chicken cage can perform poorly in a hot, humid, or high-ammonia house. When airflow is uneven, birds cluster, stress rises, and egg production becomes unstable.

H type systems often pair well with tunnel ventilation and controlled inlets because rows and tiers can be arranged to maintain consistent air paths. That consistency helps you manage temperature and moisture more predictably. In high-density houses, better airflow control can improve productivity and reduce disease pressure.

A-type and H-type can both work with good ventilation design—but H type tends to give you more “engineering room” for fans, ducts, cooling pads, and manure belt drying. When your farm targets higher bird counts, that extra control matters.

Let’s talk about what your team actually does every day. A cage choice changes:

How feed gets refilled and monitored

How eggs move and where breakage happens

How often you handle manure

How quickly you can inspect birds

In many projects, H type systems reduce walking distance and simplify inspection routes because cage rows are more uniform. That can reduce labor in egg collection, manure cleaning, and routine checks. Over time, that lowers labor costs and stabilizes staffing.

A-type cages can be easier to understand and run with a smaller team at the beginning. For medium farms, that simplicity is valuable. If you don’t plan to mix more than two major upgrades in the first phase, A-type may fit your current operational rhythm.

Reality check: if your farm scales from 20,000 birds to 100,000+ birds, the daily labor gap becomes obvious. That’s where H type often becomes the long-term efficiency choice.

Many buyers ask about bird welfare—and rightly so. Welfare is not only a policy issue; it affects flock health, stress, and consistent output. Both a-type and h-type designs can support good welfare if you control density, provide clean water, stable feed, proper lighting, and keep air quality high.

Here’s what matters most inside a chicken cage system:

Smooth wire mesh to protect feet

Proper slope so eggs roll gently

Adequate feeder space and reliable drinkers

Low ammonia and dry litter/manure zones

Easy access for monitoring and removing weak birds

In our engineering work, we often see H type systems deliver more uniform conditions across tiers because automation and ventilation are easier to standardize. That supports stable performance for each laying hen group.

If you’re supplying eggs into higher-standard markets, you’ll also want traceability and consistent operational control. A well-integrated system helps you document management routines and keep audit-ready processes.

When buyers compare a poultry cage system, they sometimes focus only on layout. But durability is often where the real ROI lives. Ask about:

Whether key parts galvanize properly (hot-dip or high zinc coating)

The galvanized wire and galvanized wire mesh consistency

Whether the weld points are smooth and strong

Corrosion resistance in humid environments

Frame rigidity under load and vibration

H type frames are typically heavier and more rigid, which helps long-term stability in stacked cages. If your goal is “run this farm for many years and keep upgrading,” a rigid frame reduces headaches.

A-type cages can still be very durable when built well—especially for moderate scale farms. The important thing is to verify coating thickness, weld finishing, and manufacturing control. As a turnkey supplier, we build the cage system as part of the whole farming equipment package—so we focus on both materials and how they perform inside the house environment.

Your cage decision should match production goals—not trends. Ask yourself:

What is your target bird number and house count?

Do you need premium egg grading and low breakage?

Is your priority fast build or long-term automation?

H type often supports higher egg production efficiency because systems are engineered for smoother egg transport, predictable feeding, and stable climate control—especially in larger houses. That’s why many integrated companies adopt h-type chicken cage layouts for standardization across multiple sites.

A-type can be a great solution for farms expanding step-by-step. If your strategy is to build one house now, prove performance, then expand, the simpler type layer approach may feel safer.

| البند | A-Type Battery Cage | H-Type Battery Cage |

|---|---|---|

| الهيكل | “A” frame, angled sides | “H” frame, vertical stacked rows |

| أفضل ملاءمة | Small–mid farms, phased upgrades | Mid–large farms, standardized expansion |

| Automation | Possible, may need more design care | Easier for full الأتمتة integration |

| Space utilization | Good, but height may be limited | Strong space utilization with more tiers |

| Manure handling | Manual/semi-auto common; belt optional | Belt manure removal is common and clean |

| Ventilation | Works well with good design | Often easier to optimize across tiers |

| Long-term scalability | Moderate | Strong for large-scale systems |

| Cost profile | Lower upfront in many cases | Higher upfront, stronger long-term efficiency |

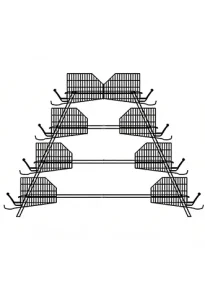

4-Tier H-Type Broiler Battery Cage

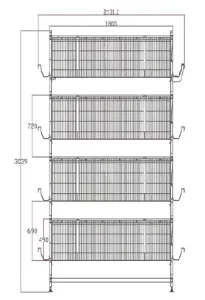

A-type 4-Tier Layer Cage

Below is a simple visual to help you decide fast. (Long bar = stronger fit.)

Budget-first build: ██████████

Simple operation: █████████

Fast installation: ████████

Full automation later: █████

High bird count: ██████████

Automation-ready: ██████████

Clean manure belt management: █████████

Standardization across farms: █████████

A regional operator wanted to start with one house and grow after cash flow stabilized. They chose a-type cages with basic feeding and manual monitoring upgrades planned later. Their priority was speed and manageable complexity. The result: stable output, simpler training for workers, and a smooth first-year operation—then a planned automation upgrade in year two.

A larger group aimed for consistent performance across multiple houses. They selected an h type layer battery cage layout with automated feeding, drinking, egg collection, and belt manure removal. Their priority was predictable productivity and reduced labor. The result: easier standard operating procedures, cleaner houses, and a simpler path to add new houses using the same blueprint.

As a turnkey supplier, our job is to match the right cage system to your farm size, labor situation, and future expansion plan—not to push one design for everyone.

Here’s a simple, engineer-friendly method I use when a buyer says, “I need to decide this week.”

Confirm your farm size (birds per house + number of houses)

Define your production goals (cost-first vs efficiency-first)

Check house constraints (width, height, fan locations, access doors)

Decide your automation level now (and what you add later)

Evaluate manure strategy (manure removal belt vs manual/semi-auto)

Verify coating and materials (galvanize, wire mesh, key frame thickness)

Run a labor plan: how many workers per house per shift?

Plan spare parts and service intervals

Ensure the cage layout matches your ventilation design

Choose the system that meets your specific needs with minimal future rework

Is H type always better than A-type?

Not always. H type is often better for larger farms because automation and space utilization are strong. But A-type cages can be the right cage solution for medium projects that value simplicity and controlled investment.

Which cage system helps egg production efficiency the most?

Usually, the one that keeps conditions stable: consistent feed, water, and ventilation, plus clean manure handling. Many large farms see higher egg production efficiency with h-type cages because automation reduces variation.

Can I upgrade A-type cages to full automation later?

In many cases, yes—but it depends on house layout and the original cage design. If you plan upgrades, tell your supplier early so the cage system is built with future routes for feeding, egg belts, and manure removal.

How many tiers are typical for A-type and H type?

Both can use multiple tiers, but H type commonly supports more tiers with strong frames. Your house height and ventilation plan often decide the final tier count.

What should I check to avoid poor durability?

Ask about zinc coating, whether components properly galvanize, the quality of weld points, and the wire finishing on wire mesh. Also confirm that the cage system is designed for your local humidity and cleaning routine.

Does a battery cage system reduce labor costs?

Yes—especially when you integrate automation for feeding, egg collection, and manure removal. A well-designed system can reduce labor and stabilize output, which is why many farms treat it as a long-term productivity investment.

A-type and H-type are both proven battery cage solutions—the best choice depends on farm size, budget, and automation goals.

H type usually wins for large-scale projects, stronger space utilization, and easier automation.

A-type cages often win for faster start-up, simpler operation, and phased upgrades.

Ventilation + manure strategy matter as much as the cage itself—good house design protects egg production.

Always verify materials and manufacturing: galvanized wire mesh, coating, and weld quality.

Choose based on production goals and a clear expansion plan, not just upfront cost.

If you want, I can turn your farm inputs (house size, target birds, climate zone, automation level) into a one-page recommendation that compares two types of layer cage layouts side-by-side.

Choosing the wrong battery cage layout can lock your poultry farm into high labor, poor ai…

نظام القمامة العميقة مقابل نظام أقفاص البطاريات لإنتاج البيض في مزرعة دواجن حديثة: استكشف أيهما...

سنرد على استفسارك في غضون 24 ساعة. للاستفسارات العاجلة، يرجى الاتصال بنا عبر WhatsApp: +86 133 6144 9578 أو الاتصال بنا مباشرة.

*نحن نحترم خصوصيتك. جميع المعلومات المقدمة سرية للغاية.

سيتم استخدام بياناتك فقط للرد على استفسارك. نحن لا نرسل أبدًا رسائل بريد إلكتروني أو رسائل ترويجية غير مرغوب فيها.