Improve Space Utilization & Reduce Labor in Commercial Layer Farming

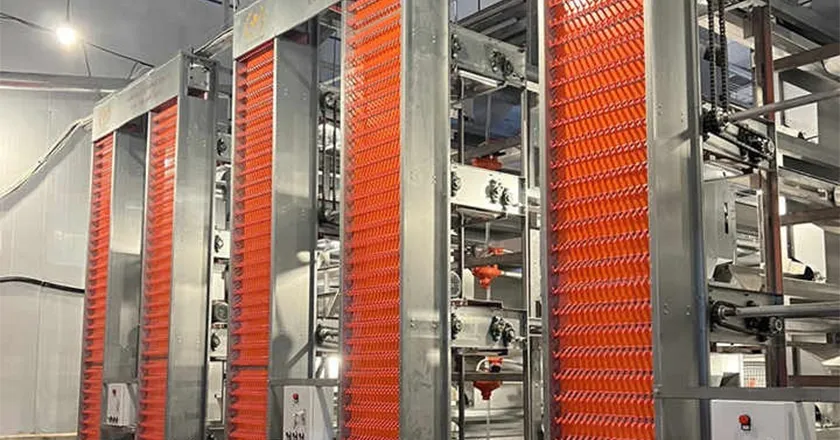

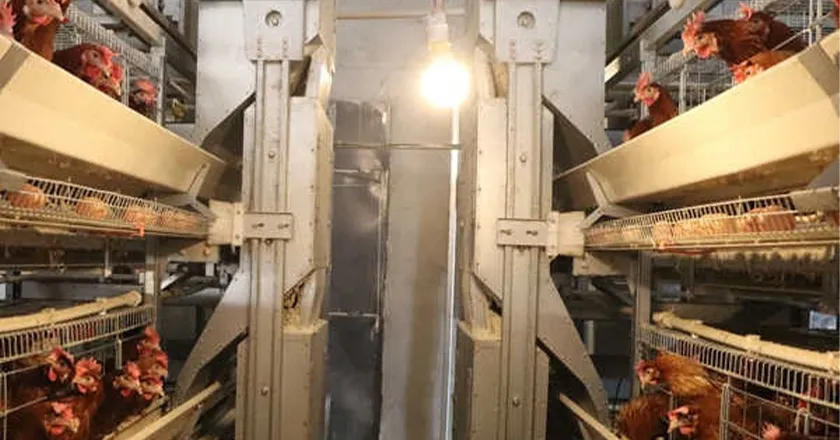

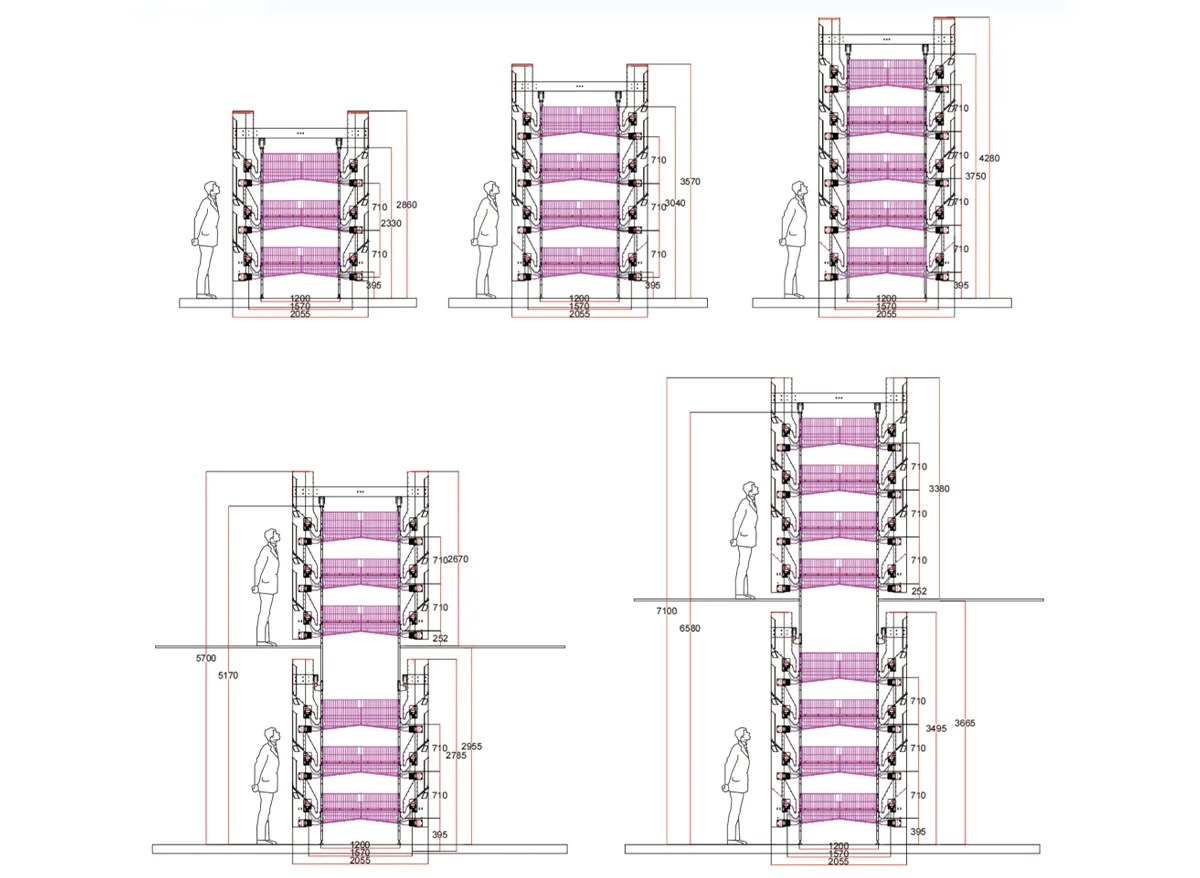

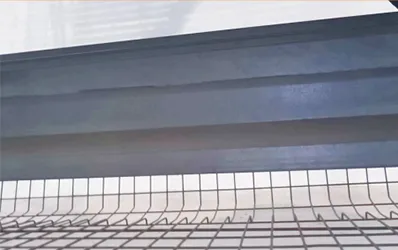

The H-Type Automatic Layer Battery Cage is designed for efficient egg production, enabling intensive breeding management with better building utilization and reduced labor cost.

The multi-layer structure improves farming density, supports stable egg production, and helps maintain a cleaner environment inside the poultry house.

This system meets the biological and behavioral needs of laying hens and is widely used in modern automated chicken farms.

Key Features of H-Type Automatic Layer Battery Cage

High space utilization and improved egg production efficiency

Lower labor cost with fully automatic management

Clean PVC water line system with anti-wet feather drinking design

Automatic water level monitoring with shortage alarm

Automatic manure removal system reduces breakage & labor

Closed environment for better climate control and stable laying rate